Using SolidWorks Hart Engineering Group can:

Construct a 3D model of a part or assembly

Alter existing models or scanned surface data

Reverse engineer a part to the specific pattern type

In-house mold, pattern, design & construction

Digital Scanning-Solid Modeling

CNC Pattern Processing

Ceramic Mold Production

Custom Thermoforming

Soft-Touch Vinyl Wrapping

Sonic Welding & Adhesive Bonding

Accurate robotic trimming & drilling

ABS, TPO, Acrylic

HDPE

Polypropylene

Polystyrene

Vinyl overlay with ABS substrate

Wood grain

Chrome

Patterned films over ABS/TPO

Using SolidWorks Hart Engineering Group can:

Construct a 3D model of a part or assembly

Alter existing models or scanned surface data

Reverse engineer a part to the specific pattern type

With our laser scanner and Geomagic software we are able to:

Scan existing parts, molds, or patterns. We can then use those scans to reverse engineer or compare new and old parts.

Let us help you go from print, to pattern, to production, in the most cost effective way possible. No print, no problem, our designers will be happy to work with you, from concept to completion.

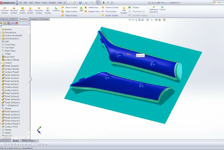

Once we have a CAD model of the pattern we:

Construct stock material for the pattern

Set up the stock material on the CNC

Import the CAD file into Mastercam and make tool paths for the CNC to cut

After the pattern is cut, it is then prepped for the mold process

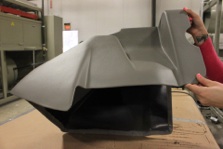

Our ceramic molds are made with premium quality resin. Each layer is hand laid for uniform thickness throughout the tool for maximum durability and premium quality.

With our computer-controlled thermoforming machines, we are capable of forming parts as large as 6‘x14’ and up to 44” deep. Our quartz heating elements and state-of-the-art forming capacities allow us to form even the most complex designs out of a variety of different materials (TPO, POLY, ABS, PETG, and Acrylic).

We can create a high end automotive look and feel by laminating custom Naugahyde Ⓡ by Uniroyal vinyl over your part.

With our ultrasonic welding and adhesive bonding capabilities, we are able to attach both reinforcing and fastening assemblies to the formed parts.

With our 7-axis robotic routers, we are able to hold very tight tolerances on trimmed edges, cutting slots, and holes in most difficult locations.